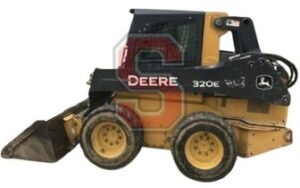

Skid Steers and Compact Track Loaders

You May Also Like

Skid Steer FAQs

Why is it called skid steer?

Because it turns by skidding its wheels or tracks instead of steering them. One side moves faster than the other to change direction.

What does skid steer do?

It’s a versatile machine for digging, lifting, grading, and moving materials.

What is another name for a skid steer?

Many people call it a “Bobcat,” which is actually a popular brand of skid steer.

Is it hard to drive a skid steer?

No, it’s easy to learn with some practice.

What is the difference between skid steer loader and compact track loader?

Use a skid steer on hard, flat surfaces like concrete or asphalt, and a compact track loader on soft, uneven, or muddy terrain for better traction.

What attachments are available for a skid steer?

Common attachments include buckets, forks, augers, trenchers, sweepers, and grapples.

Is a skid steer a bulldozer?

No. A skid steer is smaller and more versatile than a bulldozer.

Can you dig with a track loader?

Yes, with the right attachment, it can dig effectively.

Is a forklift a skidsteer?

No, but a skid steer can use forklift attachments.

Why is a skid steer better than a tractor?

It’s more compact, more maneuverable, and supports many attachments.

What not to do with a skid steer?

Don’t overload, drive on unsafe slopes, or lift people in the bucket.

Is a skid steer gas or diesel?

Most run on diesel, but some smaller models use gasoline.

What is a skid steer ripper?

An attachment used to break up hard ground or surfaces.

What is a compact track loader?

A tracked version of a skid steer for better traction and stability.

Can you grade with a track loader?

Yes, it’s excellent for grading and leveling surfaces.

What is the difference between radial lift and vertical lift skid steers?

Radial lift loaders have a simple curved lift path, making them strong for digging and pushing. Vertical lift loaders have a more upright lift path, providing better reach and stability at higher dump heights. If your work is mostly ground-level, go for radial lift. If you need frequent loading at height, vertical lift is the smarter investment.

When should I choose a radial lift skid steer?

Radial lift is best for ground-level work such as grading, digging, backfilling, and landscaping tasks.

When is a vertical lift skid steer the better option?

Vertical lift is ideal when loading trucks, handling pallets, or working at higher lift heights, thanks to its superior reach and stability.